Top 10 Lamination Machines for Perfect Finishing Results?

In the world of printing and finishing, a Lamination Machine is essential for achieving high-quality results. Renowned expert, John Smith, once stated, "A proper lamination can transform simple prints into professional pieces." This underscores the significant impact of using the right machine.

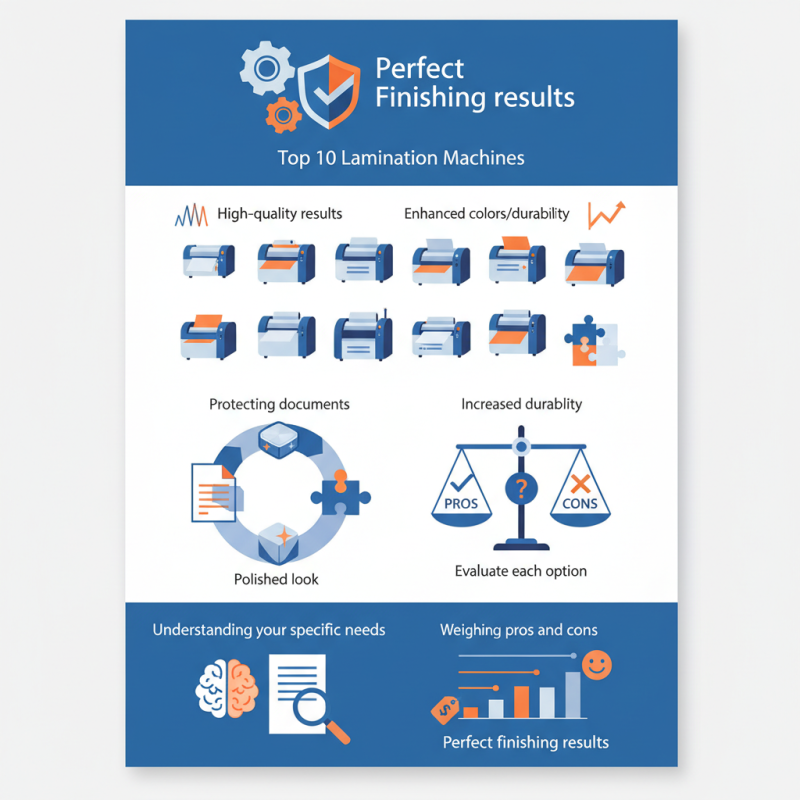

Lamination machines are vital in protecting documents from wear and tear. They enhance colors, create a polished look, and increase durability. However, not all machines deliver the same quality. Some may struggle with consistency or offer limited features. It is essential to evaluate each option carefully to avoid wasted resources and effort.

Choosing the right lamination machine involves understanding your specific needs. A machine that works perfectly for one project may not suit another. It’s crucial to weigh the pros and cons. This ensures you don’t fall into the trap of overpaying for unnecessary functions. A thoughtful selection can lead to perfect finishing results.

Overview of Lamination Machines and Their Importance

Lamination machines play a crucial role in various industries. They provide protective layers to documents, improving durability and aesthetics. According to industry reports, the global lamination market is projected to grow at a CAGR of 5.8% from 2021 to 2028. This growth emphasizes the increasing demand for high-quality finishing solutions.

Businesses rely on lamination to enhance their products. For instance, laminated materials are less prone to wear and tear. They withstand moisture, dirt, and damages. However, not all lamination machines deliver consistent quality. Users often report issues like air bubbles or uneven finishes. These challenges highlight the importance of investing in the right equipment.

Operational efficiency is another concern. A well-functioning machine can significantly reduce production time. Nevertheless, downtime due to maintenance can hinder workflow. Studies indicate that up to 30% of production time may be lost to equipment malfunctions. This statistic urges businesses to regularly assess their lamination capabilities for improved results.

Key Features to Consider When Choosing a Lamination Machine

When selecting a lamination machine, consider several key features. Think about the size of the items you will laminate. A compact machine is ideal for smaller projects. However, larger models are necessary for bigger sheets or documents. Check the maximum lamination thickness too. Machines often vary in their capability.

Speed is another crucial factor. Some machines work quickly but may lack quality. A slower machine might offer better results, so balance is essential. Don’t overlook temperature settings. A machine with adjustable heat allows for better control. It helps to prevent damage to thin materials.

Tips: Always test on a small piece first. This will save you from ruining important documents. Regular maintenance can extend your machine's life. Dust and debris can cause malfunctions over time. Reflect on your specific needs. Sometimes, smaller, simpler machines perform better than high-end options. Consider how often you will use it. A machine that fits your lifestyle is the best choice.

Top 10 Lamination Machines for Different Needs and Budgets

Choosing the right lamination machine can be overwhelming. With so many options available, it's crucial to match the device to your specific needs and budget. For casual users, a simple, lightweight machine may suffice. These models typically handle basic tasks well and are easy to store. On the other hand, businesses with high-volume demands might require robust machines that can work non-stop.

When selecting a machine, consider the types of projects you'll tackle. Not all laminators handle every material. Some may struggle with thicker pouches. So, check the specifications carefully. You want a smooth finish on all your documents. Do not overlook additional features like cold lamination settings. This option can be handy for materials sensitive to heat.

**Tips:** Always read user reviews. They can highlight issues you might face. Also, test your machine with scrap materials before doing important work. This practice helps you get a feel for its operation. Lastly, set a reasonable budget. Spending too little may lead to poor-quality finishes, while overspending can strain your finances. Balancing cost with functionality is key.

Top 10 Lamination Machines for Perfect Finishing Results

| Model | Type | Max Lamination Width | Heat-up Time | Price Range | Best For |

|---|---|---|---|---|---|

| Model A | Hot Laminator | 12 inches | 5 minutes | $100 - $150 | Home Use |

| Model B | Cold Laminator | 9 inches | N/A | $80 - $120 | Crafting Projects |

| Model C | Hot Laminator | 18 inches | 3 minutes | $200 - $300 | Small Businesses |

| Model D | Cold Laminator | 25 inches | N/A | $350 - $500 | Professionals |

| Model E | Hot Laminator | 11 inches | 6 minutes | $90 - $140 | Home Use |

| Model F | Cold Laminator | 15 inches | N/A | $150 - $200 | Artwork Preservation |

| Model G | Hot Laminator | 16 inches | 4 minutes | $250 - $350 | Educational Institutions |

| Model H | Cold Laminator | 20 inches | N/A | $400 - $600 | Graphic Design |

| Model I | Hot Laminator | 12 inches | 5 minutes | $120 - $180 | Photography |

| Model J | Cold Laminator | 14 inches | N/A | $160 - $220 | Scrapbooking |

Comparative Analysis of Performance and Durability

Choosing the right lamination machine involves understanding performance and durability. Users need a machine that laminates efficiently. It should handle different materials well. Some machines offer various settings for thickness and temperature. This flexibility can enhance results significantly. Yet, not every model handles all tasks gracefully. Users often report inconsistency in output quality.

Durability is also a key factor. A machine may perform well initially, but how long will it last? Some users notice wear and tear after a few months. It’s vital to assess the build quality. Machines with stronger components often offer better longevity. However, portability can sometimes compromise durability. A lightweight machine might be more convenient but less sturdy.

Lastly, maintenance plays a crucial role. Regular cleaning and care can enhance performance. Users should watch for jams and clogs, which can lead to frustrations. Often, simple troubleshooting can solve many problems. However, some machines may require frequent attention. This aspect can deter users seeking a hassle-free experience. Balancing performance and durability remains a challenge in the quest for the perfect lamination machine.

Maintenance Tips for Extending the Lifespan of Lamination Machines

Maintaining lamination machines is crucial for achieving perfect finishing results. Regular upkeep extends their lifespan and ensures consistent performance. A recent industry report suggests that well-maintained machines can last up to 30% longer than those that are neglected. Hence, practice careful maintenance.

Routine cleaning is essential. Dust and adhesive residue can accumulate and impair functionality. Wipe down surfaces with a soft cloth after each use. This prevents the buildup of grime that can affect operation. Furthermore, ensure that the rollers remain free from any sticky substances. Apply lubricant to them weekly; this simple step can improve efficiency.

Check the heating elements regularly. Uneven heating can lead to poor lamination results. If the machine experiences temperature fluctuations, it can produce curled edges. Replace any worn-out parts promptly to avoid compounding issues. Keeping a detailed log of maintenance can also help identify patterns and recurring problems. Aim for frequent checks instead of waiting for something to go wrong.

Top 10 Lamination Machines Performance Comparison

This chart compares the customer satisfaction scores of the top 10 lamination machines, providing insights into their performance and user approval.