What is a Roll Lamination Machine and How Does It Work?

A Roll Lamination Machine is an essential tool in various industries. It plays a vital role in the laminating process, ensuring that materials are efficiently coated and protected. This machine allows for high-quality finishes, which are crucial in producing durable products. The lamination process involves applying a thin layer of plastic over substrates, enhancing their strength and longevity.

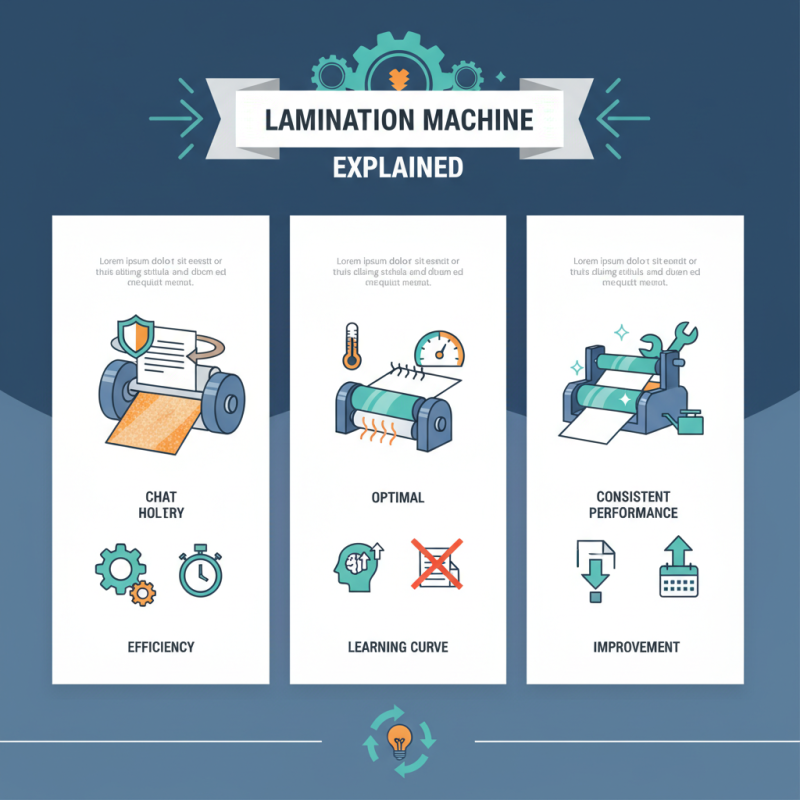

Understanding how a Roll Lamination Machine operates can help businesses save time and cost. The machine uses heated rollers to fuse materials together, creating a strong bond. Observing the workflow reveals constant adjustments for optimal results. Operators must monitor temperatures and pressure closely. Mistakes can lead to waste and inefficiencies. Learning from these experiences is key to mastering the operation.

Emphasizing the importance of maintenance is vital. Regular upkeep of a Roll Lamination Machine is essential for consistent performance. Neglect can lead to malfunctions, resulting in downtime and increased costs. Reflection on past challenges may provide valuable insights, improving future processes. Embracing the learning curve is ultimately what leads to efficiency and success in this field.

What is a Roll Lamination Machine?

A roll lamination machine is used to apply a protective layer to various materials. It’s popular in industries like printing and packaging. This machine typically consists of rolls that press and heat laminate over the material. The lamination process is crucial for enhancing durability and aesthetics.

These machines can vary in size and complexity. Some are straightforward, while others are multifunctional. They often require careful setup and adjustment. For example, the settings for pressure and temperature must be precise. A mistake here can lead to defects.

One common challenge is ensuring even lamination. Uneven pressure can cause bubbles or wrinkles. Operators need to monitor the process closely. Understanding the material type is also essential for successful lamination. Each material reacts differently under heat and pressure. This requires constant learning and adaptation.

What is a Roll Lamination Machine and How Does It Work?

| Feature | Description | Typical Applications |

|---|---|---|

| Machine Type | Continuous roll lamination | Flexible packaging, adhesive labels |

| Lamination Process | Combines heat and pressure to bond layers | Book covers, business cards |

| Materials Used | Films, paper, and other substrates | Photo prints, ID cards |

| Production Speed | High-speed operation from 10 to 100 feet/minute | Mass production needs |

| Thickness Capability | Can laminate materials from 1 mil to over 10 mil | Heavy-duty applications, signage |

Key Components of a Roll Lamination Machine

A roll lamination machine is essential in many industries. It is designed to cover materials with protective films. Understanding its key components helps to grasp its function better.

The primary part of a roll lamination machine is the heating element. This component warms the adhesive film, ensuring a solid bond. Another crucial component is the rollers. These smooth and flatten the laminating film onto the material. Proper alignment of these rollers is vital. Misalignment can lead to wrinkles or bubbles, which are challenging to fix.

Additionally, the control panel is significant. It allows operators to adjust speed and temperature. An intuitive interface can ease operation, but it can also be confusing for new users. Each machine may vary in features. Familiarizing oneself with the specific setup can enhance efficiency. Errors in setup or operation can lead to wasted materials and time. Proper training is essential to minimize these risks.

The Roll Lamination Process: Step-by-Step Overview

The roll lamination process involves several key steps that ensure a smooth operation. To begin, the operator feeds two sheets of material into the machine. These materials must be aligned properly for optimal results. Once they enter the machine, heated rollers press them together. This is where the lamination occurs, fusing the materials effectively.

After lamination, the process includes cooling. The laminated sheets pass through cooling rollers. This step solidifies the bond, preventing any warping. According to industry reports, this method increases durability by up to 30%. Many manufacturers are opting for roll lamination due to its efficiency and cost-effectiveness.

Tips: Always monitor the temperature settings carefully. Too high can damage the materials. Additionally, check the alignment of the sheets regularly. Misalignment can lead to uneven lamination, which might affect product quality. Reflecting on these aspects can improve productivity significantly and reduce waste. Remember, precision is key to achieving the best results in roll lamination.

Applications of Roll Lamination in Various Industries

Roll lamination is a versatile process used across multiple industries. This technique involves passing materials through rollers that apply pressure and heat. It creates a strong bond between layers. In the packaging sector, roll lamination helps produce flexible packaging materials. These are essential for food protection and shelf life extension. The result is high-quality, visually appealing packages that attract consumers.

In the construction industry, roll lamination enhances insulation materials. Multi-layered products improve energy efficiency in buildings. These materials also resist moisture and weather damage. The automotive sector benefits from laminated composites. They contribute to lighter vehicles and improved fuel efficiency. The process, however, requires precision and quality control. Small inconsistencies can lead to defects in finished products. Improving the lamination process is a constant challenge for manufacturers.

Benefits of Using Roll Lamination Technology

Roll lamination technology offers several benefits that enhance production efficiency and product quality. This method involves applying a protective layer to surfaces, which not only improves durability but also enhances aesthetics. According to industry reports, laminating printed materials can increase their lifespan by up to 400%. This is crucial in industries like packaging, where product presentation and longevity matter the most.

Using roll lamination can also reduce material waste. The precise application of lamination minimizes excess use of films. Additionally, advances in technology have led to more eco-friendly lamination materials that are safer for the environment. This shift aligns with the increasing demand for sustainable practices in manufacturing. It’s important to assess your current processes and see if they align with these greener options.

Tips: Always check the thickness of the laminating film. Thicker films may provide extra protection but can add weight. Also, consider choosing a machine that allows for quick film changes. This saves time and increases efficiency. Lastly, do not rush the lamination process; improper handling can lead to bubbles or wrinkles, compromising the final product’s quality.