Why Choose Enameled Aluminum Magnet Wire for Your Projects?

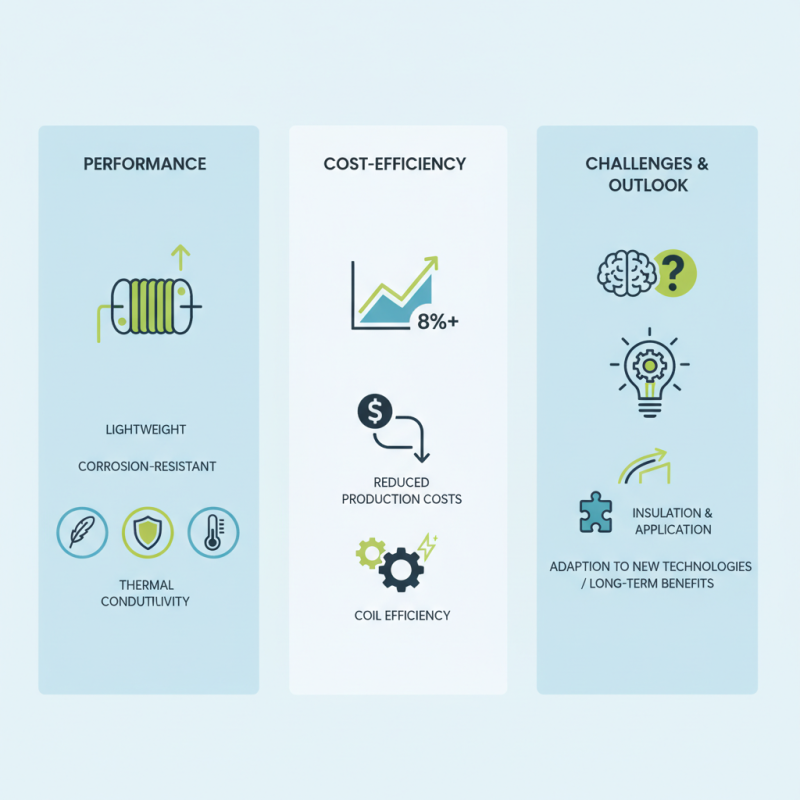

Enameled Aluminum Magnet Wire has gained popularity in various industries. It offers a balance of performance and cost-efficiency. According to a recent market report, the demand for aluminum magnet wire is expected to grow by 8% annually. This trend highlights its effectiveness in electrical applications.

Manufacturers are increasingly recognizing the advantages of Enameled Aluminum Magnet Wire. It is lightweight, corrosion-resistant, and has excellent thermal conductivity. Additionally, it provides good coil efficiency at reduced production costs. However, some projects might still favor copper wire due to its historical reputation.

Despite these strengths, using Enameled Aluminum Magnet Wire has its challenges. Proper considerations around insulation and application methods are essential for optimal performance. In some cases, engineers find it difficult to switch from traditional materials. Adapting to new technologies can be uncomfortable, but the long-term benefits can outweigh initial doubts. Exploring these aspects can lead to better project outcomes.

Advantages of Enameled Aluminum Magnet Wire in Electrical Applications

Enameled aluminum magnet wire offers numerous advantages for various electrical applications. Its lightweight nature makes it an excellent choice for industries looking to reduce weight without sacrificing performance. This wire is often favored in electric motors, transformers, and generators. The reduced weight leads to less energy consumption during operation.

One of the notable properties of enameled aluminum wire is its excellent conductivity, though it doesn't match copper. The insulation layer provides protection against short circuits. However, users must ensure proper handling to avoid damage to this delicate coating. The biggest challenge often lies in the tracking of physical damage. It’s essential to be vigilant during installation.

Corrosion resistance is another benefit, but it varies according to environment. In humid conditions, aluminum may oxidize, impacting its lifespan. Users should consider the operating environment carefully when choosing materials. This wire may also require specific tools for cutting and termination. Mistakes in these processes can lead to significant setbacks. Careful planning and execution are crucial to maximizing the benefits of enameled aluminum wire.

Advantages of Enameled Aluminum Magnet Wire in Electrical Applications

Comparing Enameled Aluminum and Copper Magnet Wire for Performance

When comparing enameled aluminum magnet wire to copper magnet wire, performance plays a critical role. Enameled aluminum is lighter than copper. This makes it easier to handle during installations. Its resistance to corrosion is another benefit. Enameled aluminum can perform well in humid environments. This is something copper struggles with over time.

Copper wires have higher conductivity, which is a significant advantage. However, aluminum offers almost the same performance at a lower weight. That’s attractive for various applications. Yet, some users find soldering aluminum to be more challenging. This can lead to connectivity issues if not done properly.

It’s important to consider these factors in your project plans. Enameled aluminum may save weight and costs, but reliability is key. Each material has its pros and cons. A careful evaluation can prevent future complications. Users often need to adjust their techniques for aluminum wire. Understanding these nuances is vital to ensure success in your electrical projects.

Why Choose Enameled Aluminum Magnet Wire for Your Projects?

| Property | Enameled Aluminum Magnet Wire | Copper Magnet Wire |

|---|---|---|

| Weight | Lightweight | Heavier |

| Electrical Conductivity | 60-65% of Copper | 100% |

| Cost | Lower cost | Higher cost |

| Corrosion Resistance | Better | Moderate |

| Thermal Conductivity | Lower than Copper | Higher |

| Application Usage | Transformers, Electric Motors | Winding, Generators |

Applications of Enameled Aluminum Magnet Wire in Various Industries

Enameled aluminum magnet wire is widely used across various industries. It's particularly found in electric motors and transformers. These components require efficient energy transfer. The wire’s insulation helps prevent short circuits. It can handle high temperatures, making it suitable for demanding applications.

In the automotive industry, enameled aluminum wire is becoming popular. Electric vehicles and hybrid systems rely on it for motors and generators. This wire is lightweight, which improves efficiency. However, some manufacturers still hesitate to adopt it due to concerns over durability.

The aerospace sector also recognizes the benefits of this wire. It is used for aircraft motors and avionics. Weight reduction is critical in aviation. Yet, questions arise about its long-term reliability in extreme conditions. Engineers must weigh advantages against potential risks. There are benefits and drawbacks to consider.

Factors to Consider When Selecting Enameled Aluminum Magnet Wire

When selecting enameled aluminum magnet wire, several factors come into play. The wire's thermal properties are crucial. Many projects require wires that can withstand high temperatures. Research indicates aluminum wire can operate effectively at temperatures exceeding 150°C. However, poor insulation can lead to premature failure.

The wire's gauge and conductivity also matter significantly. Aluminum has about 61% conductivity compared to copper. This means that a thicker gauge is often necessary for the same efficiency. According to the Institute of Electrical and Electronics Engineers (IEEE), the correct gauge choice can impact performance and longevity in applications like electric motors and transformers.

Moreover, the enameled coating type influences wire selection. Different coatings offer varying levels of insulation and environmental resistance. Some coatings are more prone to wear versus others that provide excellent protection. Careful examination of these factors can make or break a project's success. Misjudging the wire's requirements can lead to inefficiencies or, worse, complete system failures. Various studies show that nearly 30% of project failures stem from improper wire selection, highlighting the importance of this decision.

Maintenance and Safety Tips for Enameled Aluminum Magnet Wire Usage

Enameled aluminum magnet wire offers various applications, but proper maintenance ensures safety and longevity. Regular inspection of the wire is crucial. Look for any signs of wear or damage. Any exposed areas can lead to short circuits and hazards.

When working with this wire, be mindful of sharp edges. Wearing gloves can help prevent cuts. Avoid touching the wire with bare hands, especially if you have moisture on your skin, as it may compromise its insulation. It's essential to keep the workspace clear of clutter. Distractions can lead to mistakes that might damage the wire.

When winding the wire, do so evenly to prevent overlapping. Overlapping can create weak points, leading to potential failures in the circuit. If the wire is stored, ensure it is coiled properly. A disorganized coil can lead to tangles, which complicate future use. Remember, neglecting small details can result in significant issues down the line. Keeping these safety tips in mind helps ensure successful and safe projects.