What is a Damper Actuator and How Does it Work?

Understanding the functionality of a Damper Actuator is crucial for various industries. According to a recent report by MarketsandMarkets, the global market for damper actuators is expected to reach $5.4 billion by 2025, driven by increased demand in HVAC applications. A Damper Actuator controls airflow in HVAC systems, ensuring optimal performance and energy efficiency.

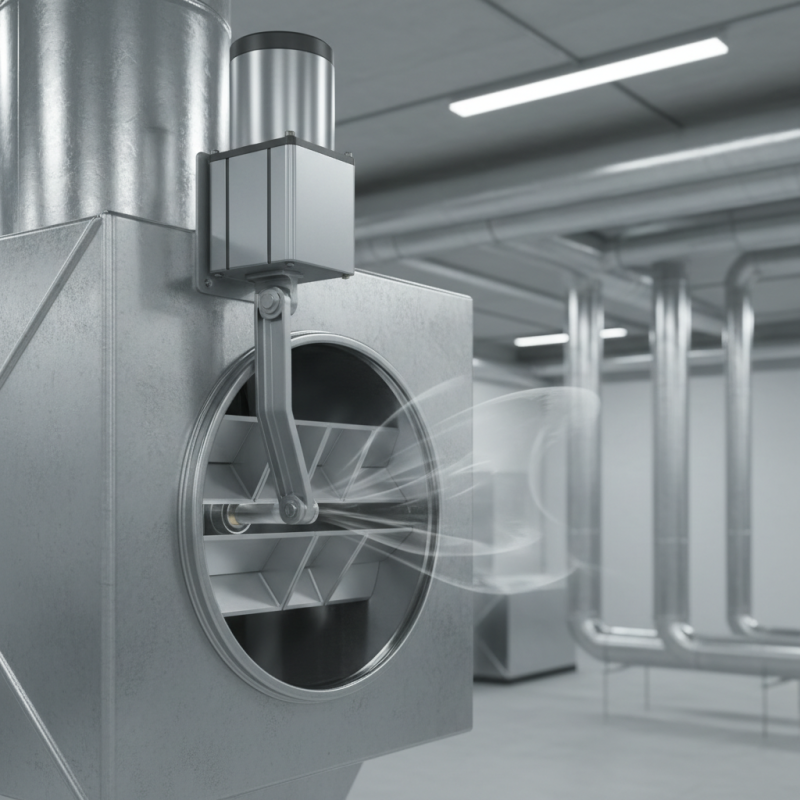

The mechanism of a Damper Actuator involves modulating damper blades. These blades regulate the flow of air through ductwork. If not functioning properly, systems can face airflow issues, leading to increased energy costs. Moreover, inadequate control can impact comfort levels in commercial and residential spaces.

Data from the American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE) indicates that improper airflow can lead to a 20% increase in energy consumption. This highlights the importance of a reliable Damper Actuator. As industries innovate, the design and technology behind these actuators are evolving. However, challenges remain in ensuring that every actuator meets precise specifications.

What is a Damper Actuator?

A damper actuator is a mechanical device used to control airflow in various systems. It adjusts the position of dampers, which are plates that regulate air movement. When the actuator receives a signal, it moves the damper to either open or close. This helps maintain desired temperature and humidity levels in a space.

Damper actuators come in various types, including electric and pneumatic models. Electric actuators use motors to create movement, while pneumatic actuators rely on air pressure. They are often used in heating, ventilation, and air conditioning (HVAC) systems. However, challenges can arise. For instance, electric actuators may face power fluctuations, impacting performance. Pneumatic actuators might be affected by air leaks, leading to inefficient operations.

Understanding how a damper actuator works is essential for optimizing systems. It plays a critical role in energy efficiency. Yet many users may overlook its importance. Regular maintenance checks on dampers and actuators can prevent issues. A small oversight can lead to significant energy loss or discomfort. Correct operation is key to ensuring effectiveness in airflow management. Recognizing potential failures early can save time and resources in the long run.

Types of Damper Actuators: A Comprehensive Overview

Damper actuators serve a crucial role in HVAC systems. They control the flow of air through ductwork, ensuring efficient heating and cooling. Several types of damper actuators exist, each tailored for specific applications. Electric, pneumatic, and hydraulic actuators are the most common variants, each with distinct characteristics.

Electric actuators are widely used due to their ease of integration. They can respond quickly to control signals. On the other hand, pneumatic actuators rely on compressed air. While they are effective in larger systems, they may require more maintenance. Hydraulic actuators, although less common, offer immense force and precision, making them suitable for heavy-duty applications.

Tip: When selecting an actuator, consider the specific needs of your system. The wrong choice can lead to inefficiency. Research shows that proper actuator selection can enhance energy efficiency by up to 30%. Be mindful of the operating environment too; temperature and humidity can affect performance.

Remember, installation is as vital as the actuator type. Poorly installed actuators can cause operational issues. The alignment and mounting must be precise. Regular maintenance checks are essential for optimal function.

How Damper Actuators Work: Mechanics and Functionality

Damper actuators play a vital role in controlling airflow within ventilation systems. They adjust the position of dampers, which are movable plates that regulate air movement. Understanding how these actuators work can enhance system efficiency.

The mechanics behind damper actuators involve a simple yet effective design. When an actuator receives a signal, it moves the damper blade to the desired position. This movement could be fully open, closed, or anything in between. Electric, pneumatic, or hydraulic power can drive these actuators. Their functionality relies on sensors and control systems that monitor and adjust airflow based on environmental conditions.

Sometimes, the system might not work as intended. For instance, blocked dampers can cause airflow issues. Improper calibration can lead to inefficient operations. Regular maintenance is necessary for optimal performance. Observing these issues and actively seeking solutions can improve airflow management significantly.

Applications of Damper Actuators in Various Industries

Damper actuators play a crucial role in various industries, providing efficient airflow control. They adjust the position of dampers in HVAC systems, allowing for better temperature management. In commercial buildings, precise control can lead to significant energy savings. The combination of sensors and actuators enhances comfort while reducing costs.

In manufacturing, damper actuators help regulate air and gas flow in processes. This can improve product quality and consistency. For instance, they are vital in the food processing industry, where maintaining specific temperatures and humidity levels is essential. However, occasional failures can disrupt production. Regular maintenance can mitigate these risks.

Automotive applications also benefit from damper actuators. They regulate airflow in engines and passenger compartments. This improves fuel efficiency and enhances passenger comfort. Yet, the complexity of these systems can lead to challenges in performance. Understanding their limitations is critical.

What is a Damper Actuator and How Does it Work? - Applications of Damper Actuators in Various Industries

| Application Area | Industry | Type of Damper Actuator | Control Method |

|---|---|---|---|

| HVAC Systems | Building Automation | Electric Actuator | Analog Control |

| Industrial Ventilation | Manufacturing | Pneumatic Actuator | Proportional Control |

| Smoke Control | Safety Systems | Spring Return Actuator | Fail-Safe Control |

| Energy Recovery Ventilation | HVAC | Modulating Actuator | Digital Control |

| Airflow Regulation | Agriculture | Hydraulic Actuator | Feedback Control |

Maintenance and Troubleshooting for Damper Actuators

Damper actuators are crucial in HVAC systems. They control airflow and improve indoor climate. Regular maintenance is key to ensuring they function efficiently. Often, these components experience issues. Common problems include noise and inconsistent airflow.

When troubleshooting, start with visual inspections. Look for loose connections or signs of wear. A dusty actuator can cause sticking. Clean the components to improve performance. It's also wise to check the power supply. A weak connection may affect functionality.

Sometimes, recalibration is necessary. Actuators can drift over time. Ensure they are set to the correct angles. Note any unusual sounds during operation. This could indicate internal damage. Keeping a detailed log helps track patterns. Ignoring small issues may lead to bigger problems. Regular attention to damper actuators can prevent costly repairs.