What Are the Benefits of Using Welded Wire Mesh in 2026?

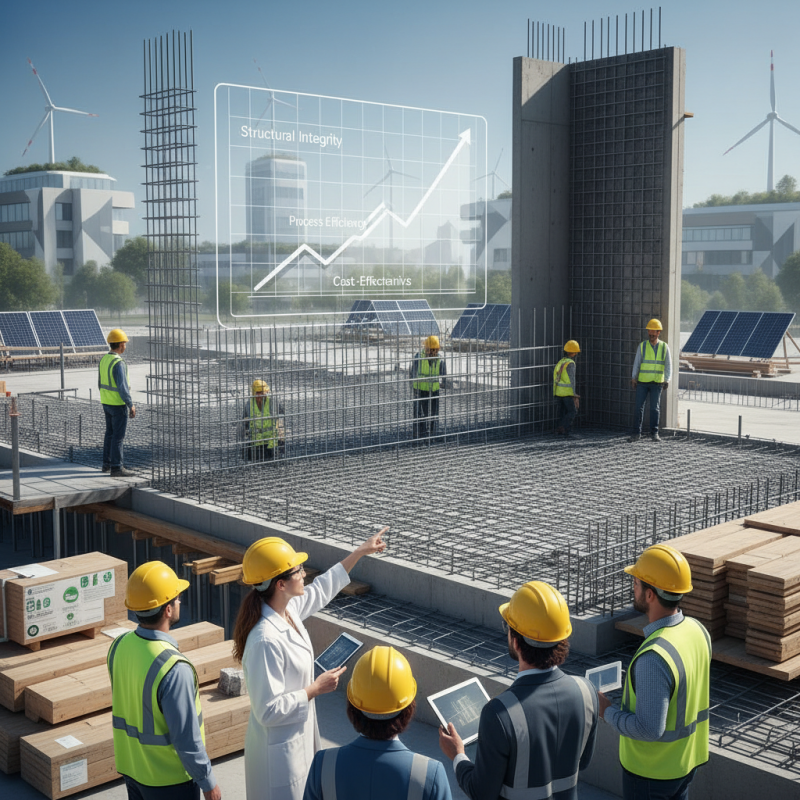

In 2026, the construction industry is evolving rapidly, and one product stands out: welded wire mesh. Renowned expert in construction materials, Dr. Alice Thompson, emphasizes, "Welded wire mesh enhances structural integrity while simplifying the construction process." This statement highlights the growing recognition of welded wire mesh in modern projects.

welded wire mesh is not just about strength. It offers versatility, making it suitable for various applications. From foundations to fencing, welded wire mesh plays a crucial role. Its cost-effectiveness is another significant benefit. However, challenges in sourcing high-quality materials remain. Some suppliers still prioritize profit over quality, affecting the overall reliability.

As we explore the advantages of welded wire mesh, we must consider the environmental impact. Sustainable sourcing is essential. Consumers and builders alike should be more vigilant in their choices. While welded wire mesh presents numerous benefits, it is vital to ensure responsible use in the industry. This meticulous approach will be indispensable for future innovations and sustainability.

Benefits of Welded Wire Mesh in Construction and Infrastructure in 2026

Welded wire mesh is gaining popularity in construction and infrastructure in 2026. Its versatility makes it suitable for various applications. Builders appreciate its strength and durability. This material can support heavy loads, ensuring structural integrity. It resists corrosion, prolonging the life of structures.

In infrastructure, welded wire mesh enhances safety. It can be used for fencing, providing security for both public and private areas. Additionally, it aids in controlling soil erosion in roads and bridges. The mesh creates a stable base for concrete, improving foundation strength. Some designs lack flexibility, which may limit usability in certain projects.

Employers often see labor savings with welded wire mesh. It simplifies installation processes, reducing time on-site. However, it’s crucial to ensure proper installation. Mistakes can lead to costly repairs. Awareness of these factors can optimize the benefits of welded wire mesh.

Benefits of Using Welded Wire Mesh in Construction and Infrastructure in 2026

Impact of Welded Wire Mesh on Reducing Construction Costs: A Data Analysis

Welded wire mesh is revolutionizing construction efficiency and cost. A detailed analysis shows a significant decrease in construction costs when using this material. In 2026, many builders report savings of up to 30% on labor and materials. The ability to cut, bend, and place easily cuts down on project timelines.

Many contractors appreciate the strength and versatility of welded wire mesh. It supports various structures, from walls to floors. However, it's essential to consider potential challenges, such as installation accuracy. A single mismeasure can lead to wasted resources and increased expenses. The initial investment might seem higher, but the long-term benefits often outweigh this.

In various regions, builders are starting to adopt welded wire mesh more frequently. The trend is growing, yet the learning curve remains. Some construction teams still face issues working with new technologies. It's crucial for firms to train their workers adequately. Adapting to change takes time, but the financial impact is undeniable.

Strength and Durability: Performance Metrics of Welded Wire Mesh Systems

Welded wire mesh systems provide exceptional strength and durability, making them a popular choice for various applications. These systems consist of intertwined wires, welded at the intersections. The result is a robust mesh that can support heavy loads. This strength is crucial in construction sectors, where reliability is non-negotiable.

The durability of welded wire mesh comes from its resistant materials. It can withstand harsh environmental conditions. This ability is particularly important in areas prone to extreme weather. However, some users may overlook the need for regular inspections and maintenance. While the mesh is strong, neglect can lead to long-term issues. Rust and corrosion can weaken the material over time if not addressed properly.

Moreover, the performance metrics show welded wire mesh is versatile. It can be used for fencing, concrete reinforcement, and even landscaping. Its adaptability allows it to meet various project requirements. However, not all applications may fully utilize its potential. Users must understand their specific needs to maximize the effectiveness of welded wire mesh. Balancing between strength, durability, and application is essential for optimal performance.

Sustainability Aspects of Welded Wire Mesh: Recyclability and Material Usage

Welded wire mesh is becoming popular for its sustainable aspects. In 2026, more industries utilize this material because of its recyclability. Made from steel or other metals, it can be repurposed after its lifespan. This reduces waste and the need for new raw materials.

Tips: Choose suppliers who prioritize sustainability. Look for certifications that indicate eco-friendly practices. This supports a healthier environment.

The process of recycling welded wire mesh is efficient. Scrap metal collectors can easily retrieve it. This minimizes the environmental impact. Yet, challenges remain. Not all facilities handle recycling properly. Therefore, do your research.

Tips: Educate yourself about local recycling options. Engage with your community to promote proper disposal. Together, we can enhance sustainability.

What Are the Benefits of Using Welded Wire Mesh in 2026? - Sustainability Aspects of Welded Wire Mesh: Recyclability and Material Usage

| Aspect | Description | Benefits |

|---|---|---|

| Recyclability | Welded wire mesh can be recycled at the end of its life cycle, reducing waste in landfills. | Promotes circular economy and decreases environmental impact. |

| Durability | Made from high-strength materials, welded wire mesh lasts longer than many alternatives. | Lower replacement costs and reduced material usage over time. |

| Material Efficiency | Utilizes less material for the same strength and functionality compared to traditional barriers. | Conserves resources and reduces carbon footprint associated with material production. |

| Versatility | Can be used in a wide range of applications, from construction to agriculture. | Increases usability and decreases need for multiple materials. |

| Cost-Effectiveness | Offers a lower total cost over its life cycle compared to other solutions. | Saves money on maintenance and replacements. |

Future Innovations: Advancements in Welded Wire Mesh Technology by 2026

The advancements in welded wire mesh technology by 2026 promise to revolutionize various industries. Innovations will focus on enhancing strength, durability, and sustainability. Manufacturers are exploring new materials that improve tensile strength without adding weight. For instance, high-performance polymers could be used alongside traditional steel. This shift may reduce corrosion and extend the lifespan of welded wire mesh.

Automation will play a significant role in manufacturing processes. Robotic systems may streamline production lines, ensuring precision and efficiency. Faster production rates could mean lower costs for consumers. However, this reliance on automation raises questions about job displacement in the industry. Will the workforce need to adapt, or will automation take center stage?

Another emerging trend is the integration of smart technology. Welded wire mesh could feature sensors that monitor integrity in real-time. This feature would be beneficial for construction and agriculture sectors, allowing timely interventions before failures occur. Yet, this technology is not without challenges. Data privacy and the costs of implementing such systems may impede widespread adoption.