Why is Aluminum Wire Coating Essential for Electrical Safety?

Aluminum Wire Coating plays a crucial role in ensuring electrical safety. This protective layer prevents corrosion and enhances the durability of wires. Without proper coating, aluminum wires can suffer from degradation over time. This deterioration can lead to electrical hazards.

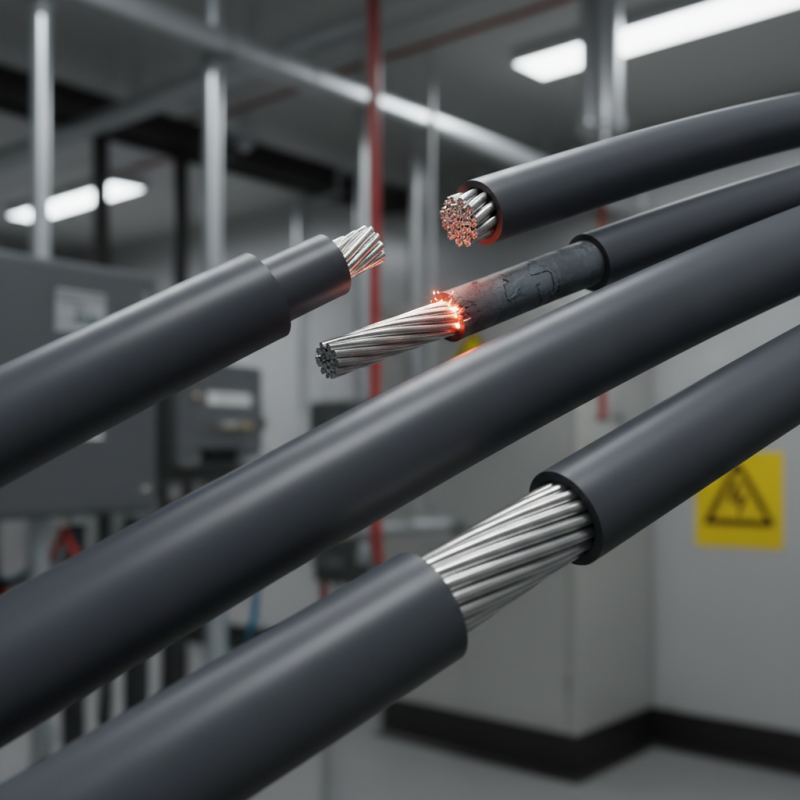

In residential and industrial settings, uncoated aluminum wires may create fire risks. The coated wires resist oxidation, ensuring a safe and uninterrupted flow of electricity. Observing the condition of wire coating is vital. A small flaw can lead to significant issues.

Maintenance of aluminum wire coating is often overlooked. Regular checks can save lives and property. Investing in quality coating materials is essential. Ignoring this could lead to serious safety concerns down the line. The importance of aluminum wire coating cannot be overstated. It is a fundamental aspect of electrical safety that deserves attention.

The Importance of Aluminum Wire Coating in Electrical Systems

Aluminum wire coating plays a critical role in ensuring the safety of electrical systems. The coating provides insulation, preventing accidental contact with conductive materials. It acts as a barrier against moisture, which can cause corrosion and weaken the wire. In areas with high humidity, this protection is especially vital. Without proper coating, aluminum wires can degrade quickly and lead to electrical failures or fires.

When working with aluminum wiring, consider these tips. Always inspect the coating before installation. A damaged or worn coating can compromise safety. Use appropriate tools to avoid gouging the wire. Small nicks can expose the metal and create hazards. It’s essential to choose the right coating for specific environments.

Education about aluminum wire care is necessary. Some people underestimate the importance of periodic inspection. Even minor issues with the coating can lead to severe consequences. Reflecting on your electrical systems means recognizing that maintenance should never be overlooked. Stay proactive, and ensure the integrity of aluminum wire in your installations.

Understanding the Role of Insulation in Preventing Electrical Hazards

Aluminum wire is widely used in electrical systems, but its safety depends on proper insulation. Insulation acts as a protective barrier, preventing accidental contact with electrical currents. Without this crucial coating, the risk of shock or fire increases significantly.

Choosing high-quality insulation is essential. Insulation materials come in various grades, and each serves a specific purpose. Poor insulation can degrade over time. This can happen due to environmental factors, wear and tear, or even incorrect installation. Regular inspections can help identify these issues early.

Tip: Look for physical signs of wear, like fraying or discoloration. If you see these, it’s time to replace the wire.

Understanding the role of insulation is vital. It not only protects live wires but also maintains efficiency. An insulated wire minimizes energy loss, contributing to a safer and more efficient system.

Tip: Keep your wiring area clean. Dust and debris can hasten insulation deterioration. Regular cleaning can extend your wire's lifespan.

Ensuring your aluminum wire is well-coated helps minimize hazards. Review your wiring regularly to prevent potential dangers. Proper insulation is not just safety; it's peace of mind.

Types of Coatings Used for Aluminum Wiring and Their Benefits

When it comes to aluminum wiring, the type of coating used is crucial for safety and performance. A common choice is PVC (polyvinyl chloride). PVC offers excellent insulation and is resistant to moisture. It protects against corrosion, which can lead to short circuits. Another popular coating is PE (polyethylene). This material is known for its flexibility and durability. It’s often used in environments where movement occurs.

Tips: Always inspect wiring for any signs of wear. Look for cracks or discoloration in the coating. Regular maintenance can prevent serious issues.

An alternative to PVC and PE is XLPE (cross-linked polyethylene). This coating can withstand higher temperatures. It's ideal for high-voltage applications. However, it can be more expensive and may require special handling. Each coating has its strengths but also comes with challenges.

Tips: Choose your coating based on the environment and application. Consider factors like temperature and humidity. Don’t overlook these details; they matter more than you think.

How Coating Improves Durability and Longevity of Electrical Wires

Coating aluminum wire is crucial for enhancing its durability and longevity. Studies show that over 30% of wire failures occur due to corrosion. A quality coating acts as a barrier. It shields the wire from moisture and environmental factors that cause degradation. This is particularly important in outdoor applications. The longevity of coated wire can increase by an average of 25% compared to uncoated wire.

Furthermore, coatings improve the wire's resistance to abrasion and impact. A report by industry experts indicates that properly coated aluminum wires can withstand over 40% more mechanical stress. This means fewer replacements and less downtime. In harsh environments, a coated wire maintains its performance under extreme conditions. However, not all coatings are created equal. Some may wear off faster than expected, necessitating periodic inspections.

While coatings serve a vital role, they aren't infallible. Even well-coated wires can suffer from localized damage. This highlights the importance of regular maintenance. Inspecting wires for wear and tear can prevent potential failures. In the end, the proper application of coatings is invaluable, yet it should be paired with good practices for maximum effectiveness.

Safety Standards and Regulations for Aluminum Wire Coating Practices

Aluminum wire coating is critical for electrical safety. It prevents corrosion and reduces electrical resistance. Proper coating ensures longevity and reliability in electrical systems. Safety standards exist to regulate this process. Compliance with these standards protects workers and property.

Regulations specify the types of coatings suitable for aluminum. They also outline application methods. For instance, coatings must adhere well to the wire surface. Insufficient adherence can lead to failures. This lack of attention to detail can cause significant hazards. Installation teams need rigorous training to meet these requirements.

Many overlook the importance of regular inspections. A neglected coating can wear down over time. Eventually, this may lead to system failures. Companies must prioritize maintenance schedules. Proper documentation and routine checks enhance safety. A proactive approach can prevent devastating incidents in the long run.

Why is Aluminum Wire Coating Essential for Electrical Safety? - Safety Standards and Regulations for Aluminum Wire Coating Practices

| Dimension | Value | Importance |

|---|---|---|

| Coating Material | Polymer-based | Prevents corrosion and enhances safety |

| Thickness Range | 0.5 mm - 1.5 mm | Ensures adequate insulation and protection |

| UL Compliance | Yes | Meets safety standards, reducing fire risks |

| Voltage Rating | 600 V | Suitable for a variety of applications |

| Environmental Resistance | Weather-resistant | Enhances durability in outdoor applications |